The keywords of international trade war, chip shortage, technology sanctions, and domestic substitution have permeated China's industrial development in recent years. In the current situation of the new Cold War, moving towards high-end manufacturing has become the inevitable and only way out for Chinese manufacturing.

Unlike the well-known Huawei chip story: going through a long process of "exchanging market for time", overcoming the difficulties of chips with sufficient cash flow and long-term resource investment.

There are still many areas of Chinese manufacturing that are not well-known to the public and face urgent bottleneck problems that need to be solved: The domestic substitution is not thorough enough, relying on global market division of labor, especially the key links of high-end manufacturing are "choked", and the quality and yield of domestic products have always been unable to improve.

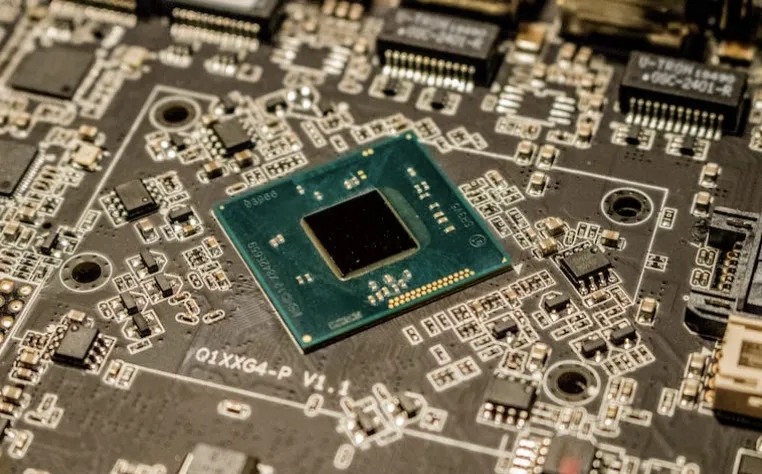

The heat sink of laser chips is the "choked throat" of the chip industry. For decades, it has been subject to the monopoly of Japanese precision manufacturing companies, with supply prices even much higher than the chips themselves. Especially in recent years, the inability to stably meet the rapid development needs of China's industrial sector has led to enormous pressure on the downstream development of high-power laser manufacturing.

The heat sink of the chip is a crucial component in the packaging and heat dissipation of high-power laser chips. The domestic market is 1 billion yuan, the global market is 5 billion yuan, and with the rapid growth of high-end manufacturing, it is also one of the industries covered by traditional material giants such as Kyocera in Japan with a revenue of 100 billion yuan.

Since 2023, two Japanese chip heat sink companies that account for over 90% of the domestic market have announced their withdrawal from the Chinese market. In the severe supply shortage environment in recent years, An Yi, the founder of Pepper Gray Technology, has basically completed the domestic closed-loop of the chip heat sink process in three years of entrepreneurship. In January 2024, the new heat sink factory of Paibo was completed and put into operation in Bao'an, Shenzhen. After complete completion, its production capacity can basically meet more than 60% of domestic demand.

Pepper Gray Technology: We have established a fully autonomous and controllable chip heat sink closed-loop process platform and mass production line, including heat sink design, ceramic pretreatment, PVD thin film process, fine electroplating, photolithography and etching, high-precision grinding and polishing, and packaging testing. We are the first high-tech enterprise in the field of industrial laser heat sink in China to integrate design, research and development, and end-to-end full process manufacturing.

Founder An Yi has served as a management team in top foreign and rapidly growing private enterprises worldwide, responsible for supply chain and enterprise operations. He founded PGT in 2021.

From high-precision ceramic materials to chip packaging, the "missing link" is gradually growing.

And the new generation of entrepreneurs are facing a more stringent environment, they need to build teams from scratch, unite upstream and downstream resources of the industry, and launch attacks on the "bottleneck" links at a faster speed.

Chewing on the hard bones of precision manufacturing has put forward higher requirements for talent reserves, organizational culture, and resource combination. The three-year research and development of Paibo has also become a new blueprint for the new generation of specialized and innovative entrepreneurship.

Lang Research Institute conducted an exclusive interview with An Yi, the founder of Shenzhen Pepper Gray Technology. Starting from the following six questions, they deconstructed Paibo's action and thought paths to overcome the "bottleneck" problem.

Q1: Why can't our predecessors solve the problem of "neck blockage"?

Q2: In the face of Japan's craftsmanship spirit, is there still room for precision manufacturing in China?

Q3: Why do some fields invest a lot of resources but cannot overcome them, leading to rent-seeking? How to avoid it?

Q4: How can a startup company that has not yet made a profit become a mission for young people to work for a lifetime?

Q5: As a high-end manufacturing ballast stone, how does a senior engineer become proficient?

Q6: Why is there a clear call for young people to enter the factory?

Q1: Why can't our predecessors solve this kind of "neck sticking" problem?

In the past, there were limitations to the understanding of localization.

We can see that the entire localization actually conforms to a certain basic pattern: from the downstream closest to the application end, gradually moving upstream. The previous person did not experience the increasingly severe trade war and barriers in our current environment, so he believes that as long as some processes can be outsourced, foreign countries can solve them, and the back-end processes can be localized, they can be labeled as "made in China".

So, domestically produced chip heat sinks do not have an advantage in terms of cost and performance improvement, and do not truly compete with Japanese competitors. This field has long been monopolized by Japanese companies on a global scale.

Firstly, the segmented market we are targeting is too small for Kyocera. He is no longer the original startup company, but a very mature company that will use Amoeba's system to calculate this business.

For example, if downstream companies in China constantly raise new demands and must continue to invest in research and development costs, while also facing cost price requirements, they may give up on this market.

We are actually mixed: on one hand, customers are chasing us to place orders; On the other hand, our mass production capability has not yet fully closed loop. Especially in the upstream precision ceramic manufacturing, China has not formed such an industrial chain, and no one has ever put forward such high requirements for these upstream enterprises.

It can only be said that everyone has their own aspirations. We tirelessly communicate with them, hoping that upstream ceramic practitioners can understand the significance and value of what we are doing, and also screen for collaborators.

Then, when ceramic suppliers are unwilling to invest more in research and development, we can use cognition and inspection standards to provide them with clearer and more detailed requirements, empowering them to produce good products.

At the same time, we also hope to openly and transparently collaborate with Japanese ceramic suppliers. I went to Japan last month, and overseas companies are actually very open. This is the principle of the market and business practices, and he will not refuse.

Our sole purpose in doing this is for China to have the right to equal dialogue with others on this competitive stage. My purpose in doing this is not to kill my opponent, but to have an equal dialogue with you.

From the current stage of development, it can be said that Japan has a higher gross profit margin, but our overall cost is better. Because the management costs of Japanese companies are higher, they have already passed the stage of entrepreneurship, and any president has a high salary.

We have an entrepreneurial mindset, and all of us in the joint venture, all of us, may have to put in a lot of time to do the work of several people. You see, I earn 20000 yuan a month, but in fact, we are still struggling.

Kyocera is considered a noble. Its executive costs may not be comparable to ours. Including his perspective on this business, it is not indispensable, and he will not be obsessed with war.

Ants have the advantage of ants, elephants have the problem of elephants.

Our material cost should be slightly higher than his, because our ceramics are not as good as theirs, and the materials and precision of domestic ceramics in the upstream are not enough. But our precious metals are all the same, and our efficiency is already much higher than theirs.

China's industrial chain, including engineer efficiency, and now our production lines are all automated, so overall, our costs have an advantage.

It can only be said that they live the life of the wealthy, while we live the life of the poor.

This is related to the growth trajectory of the enterprise and its original intention. For them, doing this is another means to achieve their original goals. For example, he entered a new industry and opened up a new product line in order to maintain his first product line. Including real estate to acquire more land to solve the original problem.

This is completely different from the entire process of Paibo, our ultimate goal is to achieve it. We are still in a high-risk period of survival and have not achieved a closed loop of autonomous hematopoiesis. In terms of technology and quality, we have achieved certain results, but from the perspective of creating profits, we have not yet achieved this.

Nothing is important in the face of survival. We are still in the survival period and will never let ourselves have any possibility of distraction. Why hasn't anyone been willing to do this for so many years? Because some smart people may come in and say that this matter is too complicated, too difficult, too bitter, they may have tried it but eventually gave up.

We have full respect, so we absolutely do not allow ourselves to blindly open up a second production line before the first product line reaches an absolute commercial closed loop. We are currently all in, allowing Paibo to independently generate blood and have an independent personality in the commercial sense, rather than relying on investors for blood transfusion.

I remember when we had 30 people at the beginning, I told them: Remember that Paibo will become a big company in the future, so you are all leaders of important departments in the future. I hope that each of us on the 30th can influence three people in the future and become the 100th person. If each of the 100 people affects another 3 people, it becomes the 300 people.

The fission of an organization is like Oppenheimer's atomic bomb: neutrons hitting different people, it is actually a fission process. I think the simple principle is to value the seed team around you, and spare no effort to create together with them all the abilities and values you need from them. For me, there's no secret to what to do, it's just "fighting dumb battles":

I was immersed in the production line, and when I encountered difficulties, I pushed down from workshop to workshop, constantly solving problems. In the end, the entire pipeline was opened. Our technicians are very strong because they follow me step by step to adjust the production line, streamline the process, and improve the yield.

I think the construction of culture and the shaping of values have no secrets, they are accumulated and done bit by bit every day and every thing. What you say and what you do are integrated, the unity of knowledge and action. That will generate a powerful force, so our team has a strong sense of mission.

Q4.2: Paibo has not yet made a profit, how can we make young people believe that I want to "work in this business for a lifetime"?

We recruit people to attract those who are similar to you and identify with each other. You have to be open and show your true self, don't pretend. When the boss dresses, the employees dress accordingly. If everyone behaves in a way that the other person likes, you won't be able to distinguish people who are similar to you during this process.

Then don't label young people, open up and chat. The core of people is similar. For example, we have a girl from 1998 who said during an interview that she cares a lot about whether to work overtime on weekends and whether she can finish work on time.

I said we actually hate overtime very much, but because we are an entrepreneurial company, it is also difficult to promise that you will not work overtime at all. This depends entirely on our work arrangements.

But after coming, I found that she worked the most overtime. I joked with her that you don't hate overtime the most, why do you always work overtime? She said I can't leave until that matter is done.

So I found that many post-95s or post-00s, or when you communicate with them, they tend to "protect themselves" and show no desire or desire. But human nature is interconnected, when he feels the atmosphere around him and the state of the people around him, he likes these people. He will be willing to do what he wants to do, he just doesn't want to be forced to work overtime reluctantly.

The first salary and bonus are definitely competitive in the industry. Most people think that Paibo is different in other companies, and they don't need to use their brains before. In other words, they just follow the script. We can't do it, we need everyone to invest and have a sense of ownership.

At the same time, we provide the team with excellent logistical support, including all of us, and basic housing is also reimbursed by the company. So provide employees with a material guarantee of worry free food and clothing.

More importantly, we have full shareholding. As long as our technicians and operators have passed the probationary period and met our basic assessment standards, they will have the original stocks of Paibo. We hope to truly make everyone the master of Paibo through this approach.

Another very important thing is that employees have found that on the basis of material conditions, the founder, Lianchuang, and all the executives of the company are eating the same things and doing the same work as them on the front line, solving all problems in one scenario. They don't feel inferior. Or feel that this matter is someone else's responsibility and I don't care. This is a very important culture.

You see, the clothes and food we all wear are basically the same.

It's not that I have a concept or philosophy first, everything is done.

As our company develops, we need to solve specific problems at every step, and because we have high requirements. So we found that everything was formed naturally.

No matter when the company is growing wildly or the future is dark, you will hope that the employees of the company can be responsible for the company both when you are present and when you are not. In addition, our initial entrepreneurial system and processes were not sound, and human abilities were crucial.

So in this process, it is our attention to the team, the state we hope they achieve, and the energy we invest that naturally arise.

Many new colleagues who came from listed companies to join Paibo were initially impressed by the strength of our technical team. They have never seen such a strong technical team: everyone has a very comprehensive engineering thinking, quality production and operation thinking.

There is actually no secret behind it. Every day we work together, each person is fully responsible for their own part. Every thing, every little thing, we build together day and night.

Let every employee know that what we say is the same as what we do, and it will form a strong belief.

I now also believe that Foxconn is a very excellent enterprise. We interviewed many people with work experience at Foxconn, who have developed professional qualities and job skills. You can't imagine it, it's definitely very excellent.

Foxconn is equivalent to TSMC in this chip industry, to put it bluntly, it is an OEM factory, but its value is unimaginable.

The ones who truly excel in our company are those who have worked in the factory, including our sales team. When we come to the company for sales, we first go to the production line, then go to the client's workshop to see if there are any problems with the products, and personally operate some of the processes. You must establish a very intuitive feel for the product in order to truly do your job well. Everything grows from this soil.

Industry must be a very important and large experimental site. The technical team is a crucial core asset for manufacturing enterprises.

When recruiting, our most important principle is "pure and good background color". Because what we are doing is not an industry with many experienced industrial workers and engineers in China before, we are the first to do this, so there are no experienced people. So the background color is very important.

We will have very open communication during the interview: daily relationship with parents; What is his value orientation when making major decisions in life? Whether it's choosing humanities or sciences, universities, majors, companies, or even choosing who to be with... these things will create a lot of communication. More often than not, it's about observing his state and feelings.

I used to see young people and white-collar workers coming out of office buildings in places like CBD and Nanshan, holding a cup of Starbucks. I think most people are actually quite miserable, maybe they didn't choose the right one. Many years ago, I called on young people to go to factories and do some solid work. With the accumulation of time, your experience, ability, and industry value can steadily increase in proportion.

This process is actually a dimensionality reduction blow. Because most people are unwilling to go, it is very valuable. Excellent college students are like fish in water in factories, and they have a very strong "relative advantage" because the talent density is not so high, the starting point is very high, and they are easily valued. Make another solid industry, as long as it has industry credibility, whether it is procurement, operation, manufacturing, engineering, or quality, manufacturing companies need such talents.

The older you get, the more popular it becomes, rather than worrying about being laid off at the age of 35 or 45.

Epilogue: Only with a calm heart can one cross the cycle

Over the past 40 years, the reform and opening up and the Internet have swept in, and everyone of us has been involved. It seems that if you don't catch up with the trend, you will be left behind by the times.

But looking back, 'I saw him rise a tall building, I saw his building collapse.'. On the contrary, by deeply cultivating the industry and continuously accumulating positive results, one can transcend bull and bear cycles to realize personal value.

It may seem like becoming a 'servant' of a certain mission or cause, but in reality, one's heart is extremely stable and full.

Finally, we conclude this interview with a question that may be relevant to how everyone spends their life:

Question: "When did you make up your mind that this is my lifelong mission

Answer: "Actually, every day, this feeling is strengthening. Our big brother Kyocera has worked for 100 billion, but we haven't achieved 100 billion yet. This must be a difficult and correct thing, and it's long and difficult. The more I do this, the more confident I become, and I constantly receive positive feedback in the process. This is something that can be done for a lifetime.

Working is not an infinite game, only entrepreneurship is an infinite game. This is also very similar to a company. At the groundbreaking ceremony of our new factory today, I also said that today is a day of extraordinary significance for Paibo. But for the future, for our lifelong career, it will be another very ordinary day. You don't know what will happen in the future.

Now the social value system is returning to rationality more and more, after squeezing the foam clean. Everyone realizes that what they can do in their lifetime is limited.

Being able to do a very small thing to the extreme and help the industry and the country solve a specific problem, I feel that the meaning of life has been realized