- Solutions in Industrial Laser Field (High Heat)

- Graphics customized according to customer requirements

- The solder type and parameter proportion can be customized according to the customer's packaging process

- According to the customer use scenario, the film structure and thickness are designed to meet the stress match and achieve the optimal effect of cos

| Application Scenario | Chip Power | 50W and Below | 50W Above | |

| Chip Material | GaAs | |||

| Solution | Project | Specification | ||

| Ceramic Substrate | Material | AlN | SiC | |

| Thickness | 0.25~0.4mm | 0.25~0.4mm | ||

| Thermal Conductivity | 230W/m·K | 400W/m·K | ||

| Metal Film | Film Structure | Ti/Cu/Ni/Au | Ti/Cu/Ni/Au | |

| Copper Thickness | 75±15um | 75±15um | ||

| Gold Thickness | Au>1um Ra<0.1um | Au>1um,Ra<0.1um | ||

| Solder Type | AuSn | AuSn | ||

| Solder Proportion | Au 75±5% Sn 25±5% (Customizable) | Au 75±5% Sn 25±5% (Customizable) | ||

| Thickness | 1.5~7um Customize as required | 1.5~7um Customize as required | ||

| Pattern Precision | Customizable L/S=100um/150um | Customizable L/S=100um/150um | ||

| Others | Cutting Precision | ±50um | ±50um | |

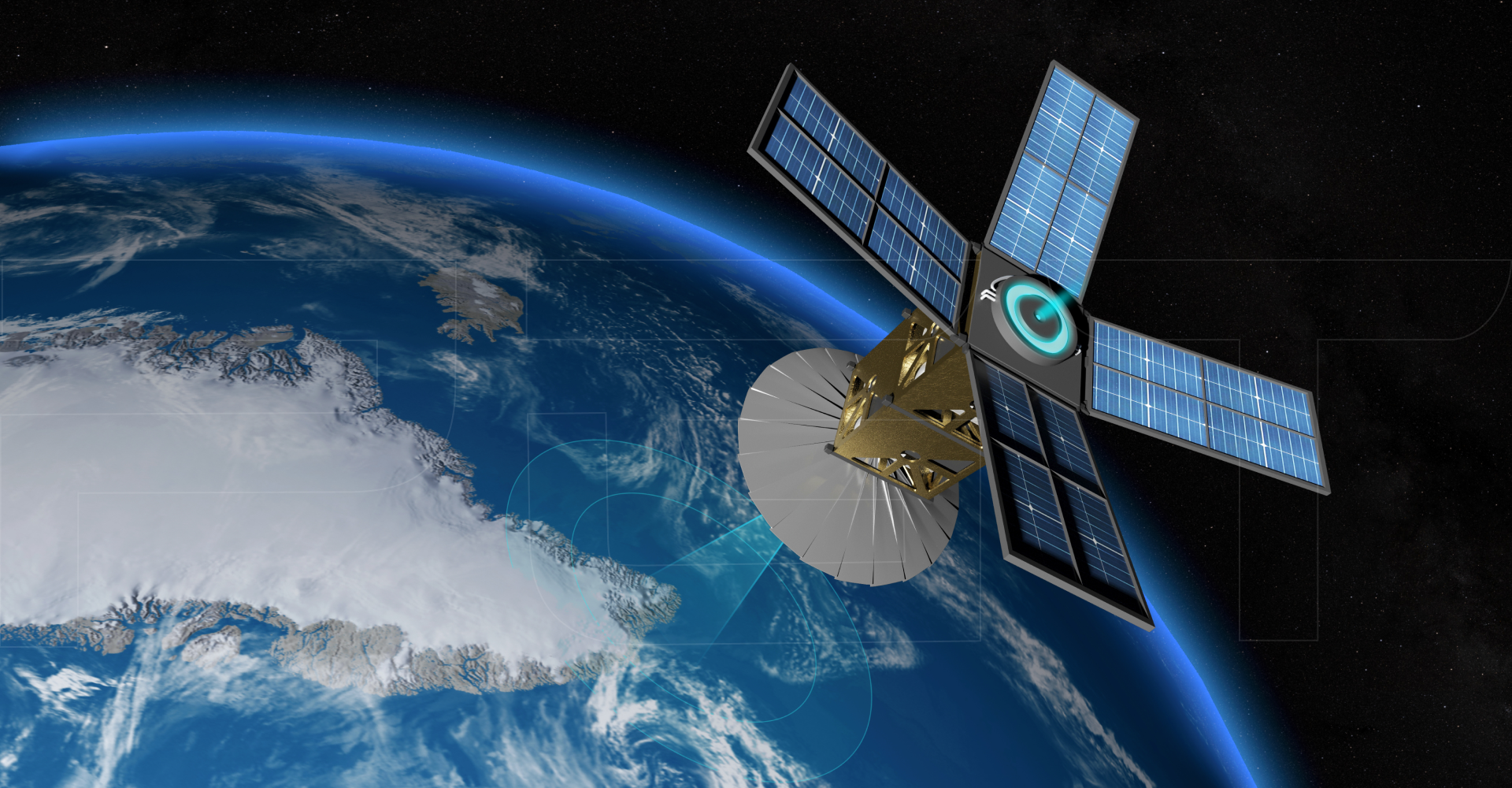

- Product application

- Applications

In the automatic production line, laser cutting and welding are common processing technologies. The ceramic heat sink can effectively manage the heat of laser, ensure the stability and durability of the equipment under high-load operation, and improve the precision of cutting and welding. The laser sensor plays a key role in automatic detection. The ceramic heat sink can maintain the temperature stability of laser emitter, ensure the measurement precision in the detection process, and is applicable to dimension measurement, surface detection, etc.