On January 3, 2024, Pepper Gray Technology's chip heat sink factory was completed in Songgang Jiangbi Environmental Protection Technology Innovation Industrial Park, Bao'an District, Shenzhen. After full completion, the monthly output value will reach 5 million pieces, which will not only become the largest laser heat sink factory in China, but also the largest modern factory in the field of chip heat sink subdivision in the world.

The chip heat sink track focused on by PGT belongs to a segment of high-power laser chips. "Laser chips" belong to high-end manufacturing, but in recent years, the vast majority have been replaced by domestic production. Except for the heat sink ceramic heat sink segment, it has been monopolized by Japanese and American companies.

PGT

In fact, China has experienced rapid growth in the downstream of high-power laser manufacturing, such as high-speed rail, new energy vehicles, including military and aerospace industries, in recent years and into the future. That is to say, China is almost the largest application market for chip heat sink, but there is a lack of heat sink in laser chips. Completely constrained by Japanese companies, even now laser chip heat sinks are more expensive than the chips themselves.

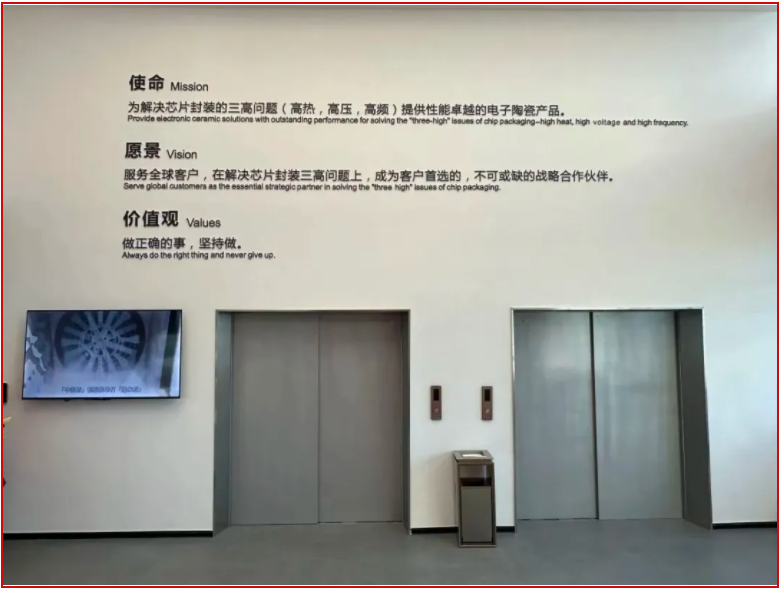

Mission, Vision, and Values

PGT founder An Yi explained to the media, "The chip heat dissipation is stuck in three high problems: high heat, high voltage, and high frequency. These are the biggest pain points, and PGT is determined to solve these three problems from the root of the production chain, together with domestic manufacturers upstream and downstream

So, since its establishment, PGT has been committed to using a domestic supply chain to replace the previous industrial chain that could only rely on Japan, Europe, and the United States. The entire process, including heat sink design, ceramic pretreatment, PVD thin film technology, fine electroplating, photolithography and etching, high-precision grinding and polishing, will be closed-loop implemented at the heat sink factory in Bao'an, Shenzhen.

Partial workshop

After the completion of the new PGT heat sink factory in Bao'an, it will greatly expand the production capacity of the original factory and become the largest domestic supplier of heat sinks. At the opening ceremony of the new factory, An Yi, General Manager and Fu Jingzhi, Deputy General Manager of PGT Technology, delivered speeches. Ai Min, Chairman of Rice Venture Capital Fund, Liang Yan, Director of Dongguan State owned Assets Supervision and Administration Commission, and Zhang Yuanxing, Secretary of Songgang Street Office in Bao'an District, Shenzhen, also gave speeches, comparing PGT Technology to China's "future Kyocera".

Opening Speech

As a sub field of chip heat sink, PGT is committed to delivering high-performance products in an industrialized, efficient, and large-scale manner, helping customers explore more application scenarios to the greatest extent and at the fastest speed possible. It aims to "knock down" the cost of chip heat sink that has been locked in by overseas giants, and work with domestic players in high-power laser and high-end material manufacturing to tackle this tough nut.